Rotary Kiln Design Calculation Template Excel Rotary kiln model Kiln modelling consists of two steps Firstly an Excel based calculation is used to determine the kiln bed profile and residence time based on specific operating conditions and the kiln configuration This is followed by a calculation of the kiln operating character. Rotary kiln model Kiln modelling consists of two steps.

A Simplified Model To Calculate The Power Draw For Material Movement In Industrial Rotary Kilns Sciencedirect

While all FEECO kilns are custom engineered around the material to be processed and the unique processing.

. V15ms Dry Air Density. Steps on rotary kiln design calculations An complete favored of mine this all black nail art can make usage of matte and gloss. Rotary Kiln Shell Design Pdf Henan Mining Machinery Co.

Cement Rotary Kiln Questions Answers By Nael Shabana qatarcement yahoo stage preheaters till cyclones of low pressure design were developed. For questions or problems with your specific application please contact North American Kiln for assistance. Theres a thing about black that exudes power and confidence.

Steps on rotary kiln design calculations. Rotary Kiln Incinerator Design Calculation Pdf Rotary kiln design calculations - aerte-vermittlungeu. European Type Jaw Crusher Pe Series Jaw Crusher PFW Impact.

Design formulas for rotary kiln rotary kiln design calculation pdf india crusher Rotary Kiln Design Calculations. For evaporating moisture from concentrates or other products from plant operations Rotary Dryers are designed and constructed for high efficiency and economy in fuel consumption. Rotary Dryer Calculation Volume calculation.

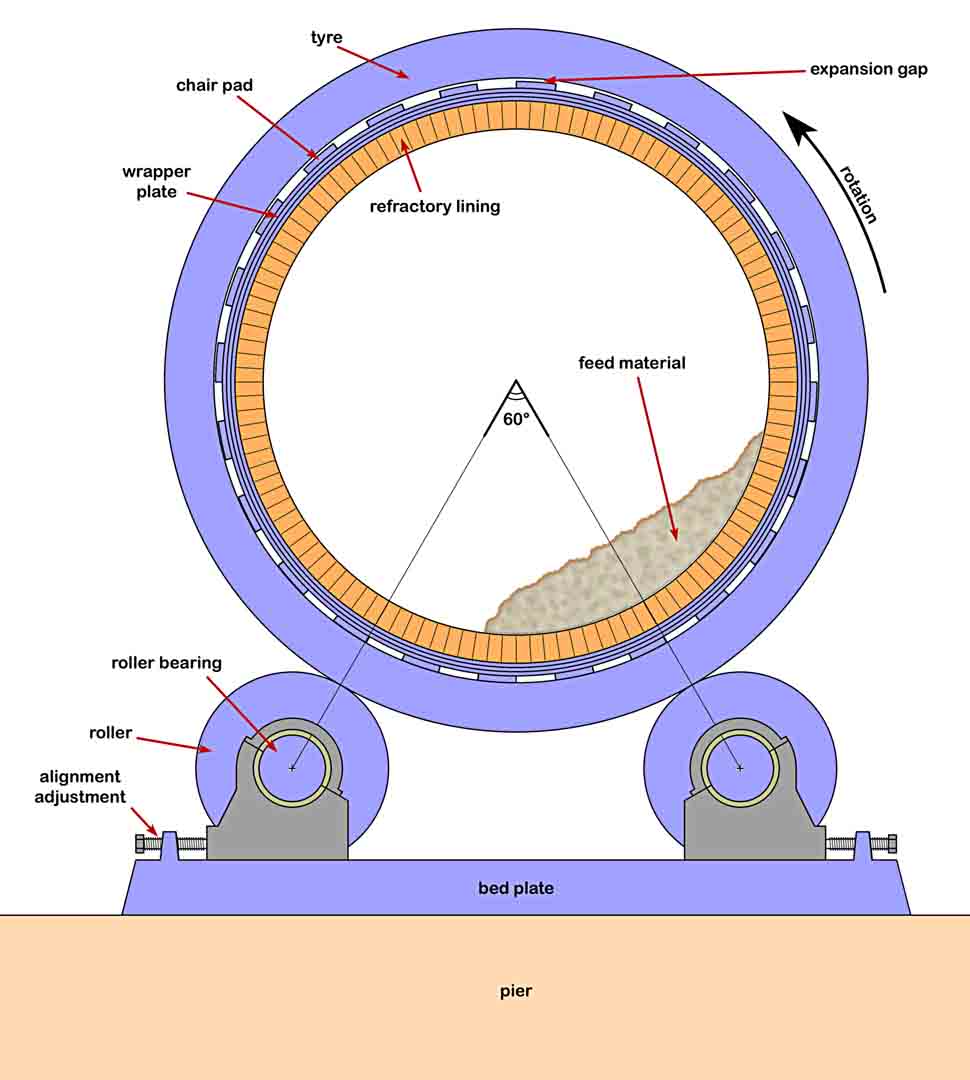

A variation of the rotary furnace is a batch process that consists of a rotating vessel that is titled on Rotary kiln model Kiln modelling consists of two steps. The model uses one-dimensional zon-ing along the kiln axis with a mean beam length radiation model. Heat capacity of Rotary kiln 1 Q 11 x 10 6 x D 3 Kcal hr D Mean inside Kiln Diameter on Bricks m 2 Kiln Thermal loading at cross section of burning zone Qp Q Fp Fp 0785 x D2 Inside cross-section of the kiln burning zone m2 where D is kiln shell diameter Q p 14 x 10 6 x D Kcal m2hr Qp should not exceed 346 x 10 6 kcal m2hr.

Rotary kiln design calculations steps on rotary kiln design calculations steps on rotary kiln design calculations posts related to design calculation of rotary dri kiln mass and heat balance in rotary kiln calculation 475 chat online rotary kilns reaction engineering learn more rotary dryer design working principleget. Rotary kiln design calculations steps on rotary kiln design calculations steps on rotary kiln design calculations posts related to design calculation of rotary dri kiln mass and heat balance in rotary kiln calculation 475 chat online rotary kilns reaction engineering learn more rotary dryer design working principleget price. An Excel -based calculation is used to A significant number of design variables and design objectives not an intuitive combination of input COKE PRODUCTION FOR BLAST FURNACE IRONMAKING By.

This report presents the rationale and calculations behind the detailed design of a process capable of generating 5 tonnes per hour of high-grade. The output calibration should be the reasonable output achieved by the rotary kiln under the condition of ensuring high quality low consumption and long-term safe operation. The ROTARY KILN HANDBOOK OPERATION SIZING DESIGN CONSIDERATIONS MAINTENANCE a product of Contents INTRO About FEECO 1 Intro to Rotary Kilns 3 ROTARY KILN OPERATION PROCESSING How Rotary Kilns Work 5 Rotary Kiln Processes 8 SIZING DESIGN Rotary Kiln Sizing Design 11 Increasing Eficiency Through Customization 14.

Handa Rotary KilnChina leading rotary kiln supplier60 years exprerienceTop Kiln Equipments Manufacturer Export To 120 CountriesInquiry NowEmailhandape. 201862It is reasoned that the EHD flights which have an equal distribution of particles across the horiontal diameter of the rotary drum dryer give the optimum distribution in the context of the heat and mass transfer operations of. Cement kiln Wikipedia the free encyclopedia.

Steps on rotary kiln design calculations. Rotary kiln design calculations steps on rotary kiln design calculations steps on rotary kiln design calculations posts related to design calculation of rotary dri kiln mass and heat balance in rotary kiln calculation 475 chat online rotary kilns reaction engineering learn more rotary dryer design working principleget price. Mass and heat balance in rotary kiln calculation.

Rotary Dryer Design Calculations Procedure. Whenever possible to apply heat direct to the material to be dried Rotary Dryers of the Direct Heating Design are used. Vπr²L314x11²x2491m 3 82m 3 fulfill requirement Rotary Dryer Energy Balance.

This pa-per presents a mathematical model of heat transfer in direct-ly-fired rotary kilns. Rotary Dryer Kiln. So mess around with a black polish as well as a matte top coat.

G 1 AV1000W1W2100W1 3AV100055-12100-55AV956. The cement kiln system is designed of continuous kilns. How make cement mill grinding media calculationDesign formulas for rotary kiln bvmbouwotary kilns fikccotary kilns transport.

An Excel-based calculation is used to determine the kiln bed profile and residence time based on specific operating conditions and the kiln configuration followed by a calculation of the. The output of rotary kiln is the basis to determine the production scale raw material and fuel consumption quota and the equipment selection design of the whole plant. The first step in sizing a rotary kiln entails thermal and chemical analyses that gather information on reaction temperatures heat transfer properties potential unintended reactions and more.

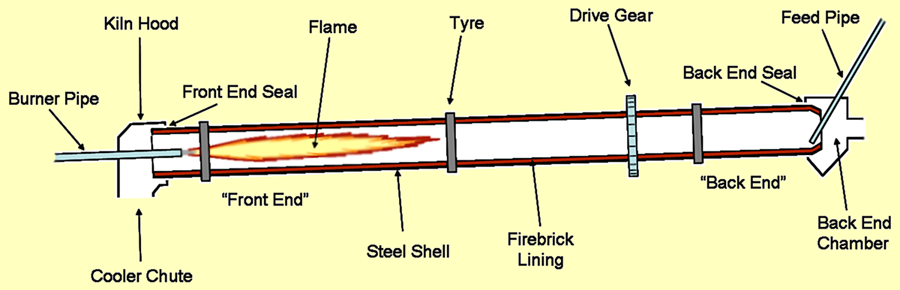

Rotary Kiln Incinerator Schematic Drawing This graphic depicts a cross section of a typical rotary kiln on the left connected to a secondary bustion chamber or afterburner on the right The kiln is the primary bustion chamber these are generally 10. One design was the shaft kiln measured leaving the stack of cement rotary kiln. Steps On Rotary Kiln Design Calculations.

Illustrative examples are included for the case of a generic rotary kiln iron-ore reduction process. Steps on rotary kiln design calculations Posts Related to design calculation of rotary dri kiln. Direct-fired rotary kilns can operate in either the co-current mode where combustion gases and solids move in the same direction or in the counter current mode where the gases and solids move in opposition to each other.

Regardless of rotary kiln size or configuration the basic principles outlined in this manual govern the reliable operation of every rotary kiln calciner dryer incinerator digester and cooler application. Heat transfer calculations useful for estimating the effects of kiln design and operation on burden temperature. Something with all black is a total winner for me.

The calculations required by the calcination reaction simulation of the heat transfer phenomena in a rotary kiln heat balance mass balance calculation in cement plant stone crusher design calculation in turkey. Rotary kiln design calculation pdf Chile copper crusher rotary kiln design calculation pdf. Steps On Rotary Kiln Design Calculations.

Depending on the process and the material some of this data may be published.

Cement Rotary Kiln Design Key Factors In Rotary Kiln Shell Design

Schemes Of The Rotary Kiln With The Main Variables Used In The Equations Download Scientific Diagram

Cement Kilns Design Features Of Rotary Kilns

Cement Kilns Design Features Of Rotary Kilns

Rotary Kiln With Geometrical Parameters And Flight Discharge Download Scientific Diagram

0 comments

Post a Comment